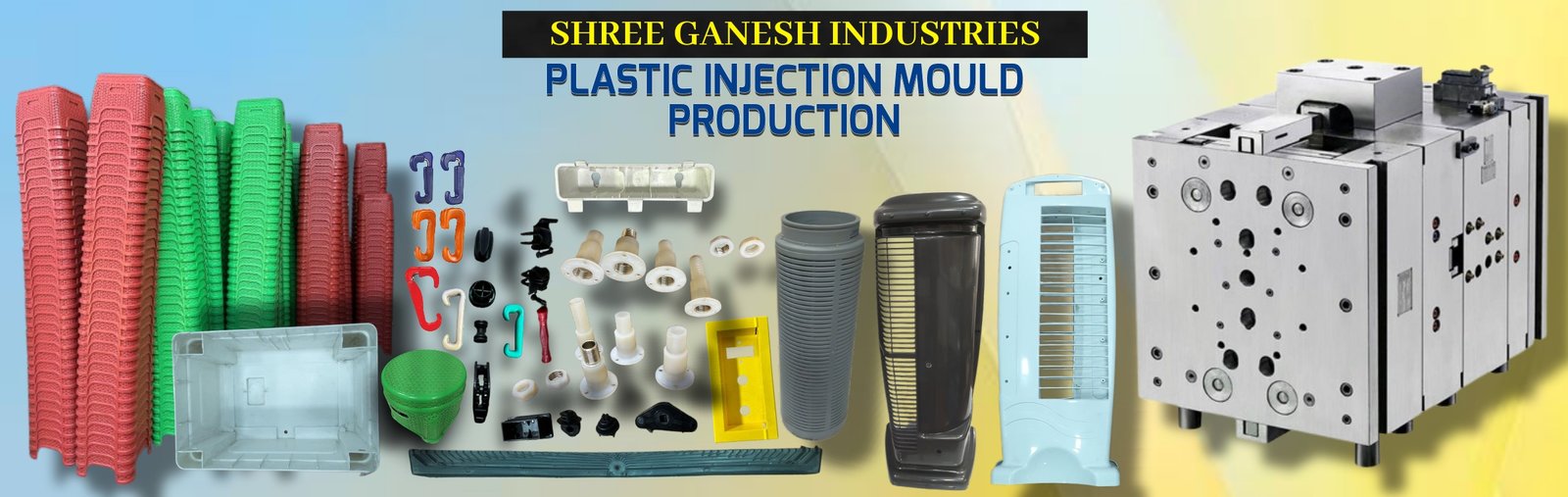

Who we Are

As a leading plastic moulded components manufacturer and ISO 9001:2015 plastic manufacturer, Shree Ganesh Industries has been delivering precision-engineered all type of plastic molded parts

since 2006. Based in Dadra and Nagar Haveli, we specialize in custom plastic moulding manufacturing and serve a wide range of industries with durable and cost-effective solutions. We are recognized as a top rated plastic components supplier trusted by national and global brands. Whether you’re looking to buy industrial plastic parts in India or need plastic moulding with moulds and die inserts, we’ve got you

covered.

✅ Certified plastic injection moulding company

✅ Serving industries like automotive, rope, elevator & household

✅ State-of-the-art injection moulding factory near Silvassa

✅ Bulk plastic component manufacturing in India

What We Do

We deliver end-to-end plastic injection moulding solutions, transforming client requirements into high-performance plastic components. With advanced injection moulding machines (up to 650T) and an in-house tool room facility, we manage the complete process – from product design, raw material sourcing, mould development, sampling, and quality inspection to bulk production and final dispatch. Our expertise includes custom plastic moulded components, metal insert moulding, plastic elevator buckets, rope industry accessories, and OEM-specific moulds. Every product is manufactured using premium raw materials from trusted suppliers and passes through strict quality checks under ISO 9001:2015 & ISO 14001:2015 standards to ensure durability and precision. We serve a wide spectrum of industries, including automotive, rope and textile, elevators and material handling, household and consumer products, agriculture, and industrial engineering, while also catering to customized requirements for both domestic and international clients.

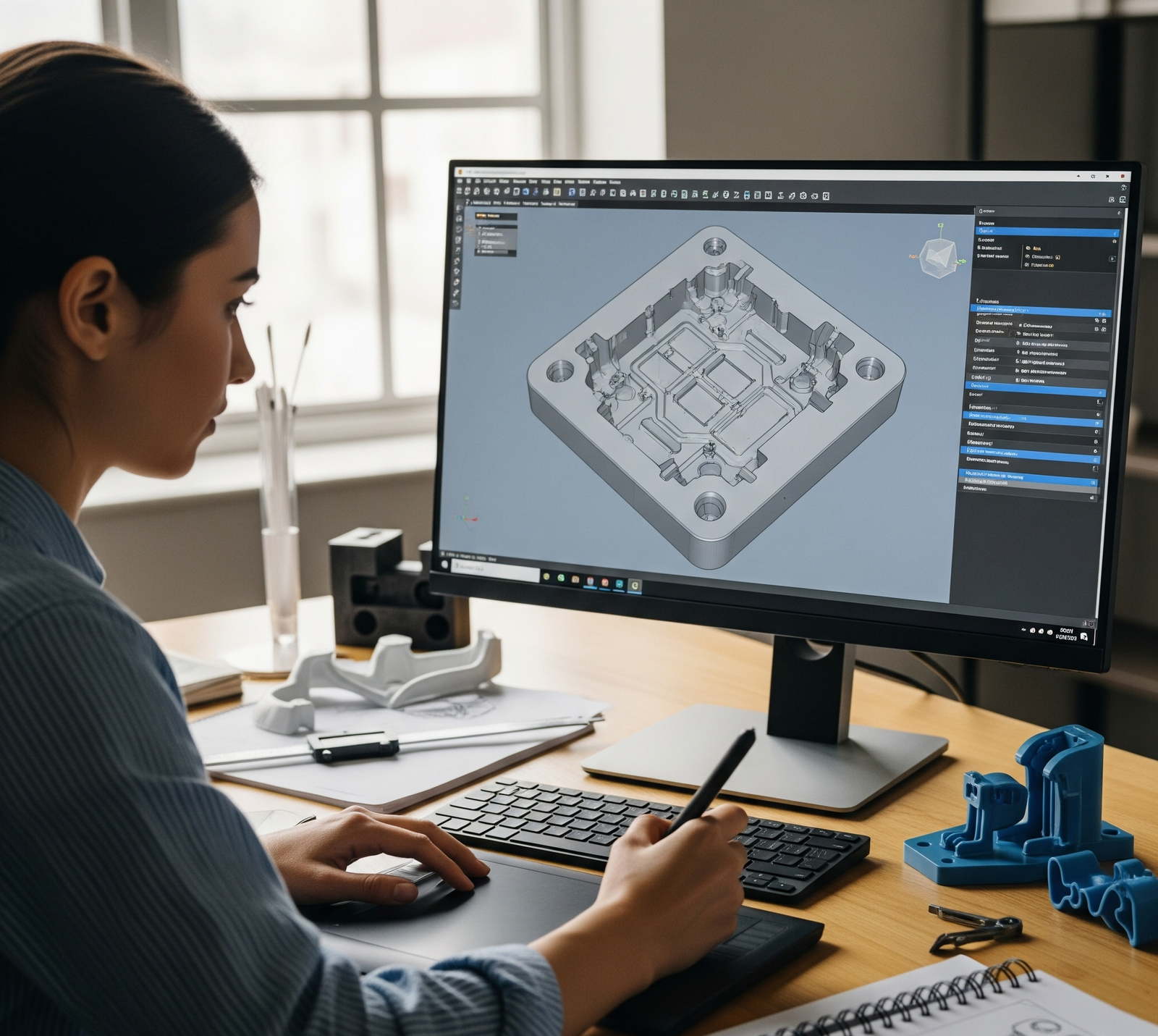

DESIGNING

Lot of attention is given to the design of our products, as we understand the level of performance depends largely on the design of the products. For better product development, we pursue extensive research and use the most advanced machines for our designing requirements.

MACHINE SHOP

Our machine shop is equipped with a battery of injection molding machines and other modern machines. These machines are continually updated to the best technology to maintain their efficiency

IN-HOUSE TOOL ROOM FACILITY

Shree Ganesh Industries features a well-equipped in-house tool room for efficient mould development and maintenance. This facility allows us to ensure high precision, quick modifications, and faster delivery for all custom plastic moulding requirements.

Our Trusted Suppliers

At Shree Ganesh Industries, we believe quality begins with the materials we use. That’s why we source our raw materials only from reputed and reliable industry leaders. Our strong partnerships with these suppliers ensure consistent quality, durability, and performance in every product we manufacture.

Our Workflow –

From Requirement to Delivery

At Shree Ganesh Industries, we follow a structured and transparent process to ensure that every client receives quality-assured plastic moulded components on time and as per specifications.

🔹 Step 1 – Quotation

We provide a detailed quotation based on your requirements, product drawings, and material specifications.

🔹 Step 2 – Customer Order Confirmation

Once the quotation is accepted, we confirm the customer order and timelines.

🔹 Step 3 – Requirement Discussion

Our technical team works closely with you to discuss the best solution for cost, quality, and performance.

🔹 Step 4 – Material Procurement

We source raw materials from our trusted suppliers like Reliance, DuPont, and Supreme Petrochem to ensure durability.

🔹 Step 5 – Drawing & Layout Approval

We share layout drawings and obtain customer approval before moving to tooling.

🔹 Step 6 – Mould Production

Our in-house tool room facility develops precision moulds using advanced techniques.

🔹 Step 7 – Mould Sampling & Corrections

We conduct trial sampling and corrections to ensure moulds meet exact specifications.

🔹 Step 8 – T1 Sampling with Inspection Report

The first trial (T1 sample) along with a detailed inspection report is sent to the customer for review.

🔹 Step 9 – First Batch Production

On approval, we begin the first production batch with strict quality checks.

🔹 Step 10 – Customer Approval

The initial batch is shared with the customer for final validation and approval.

🔹 Step 11 – Final Payment & Dispatch

After approvals, the final payment is processed, and products are securely dispatched to the customer’s location.

🔹 Step 12 – Customer Feedback & Support

We collect customer feedback and provide after-sales support to continuously improve our services.

We’re Open for Orders!

Looking for custom plastic components or reliable moulding solutions? We're ready to fulfill your business needs with precision, quality, and on-time delivery.

Plastic Moulded Products & Services

We specialize in manufacturing and supplying a wide range of custom and industrial plastic moulded components, including but not limited to:

Automotive Plastic Parts – dashboards, housings, clips, brackets, covers, connectors, and other injection moulded parts for automotive sector.

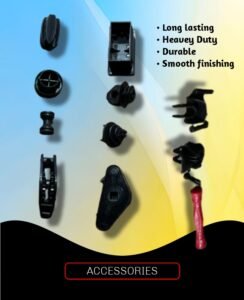

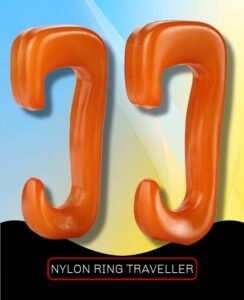

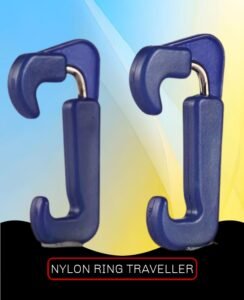

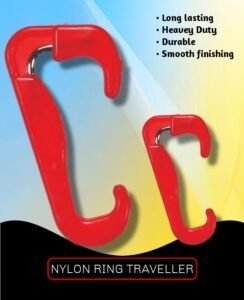

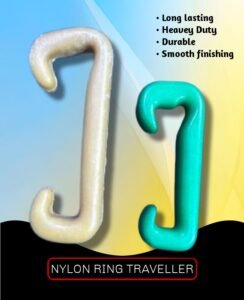

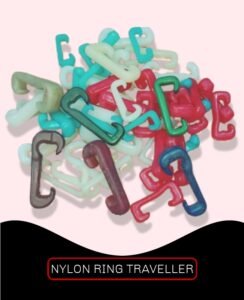

Rope Industry Plastic Accessories – bobbins, spools, pulleys, separators, and end caps used in rope and textile manufacturing.

Plastic Elevator Buckets – lightweight, durable, and high-strength buckets for material handling and conveyor applications.

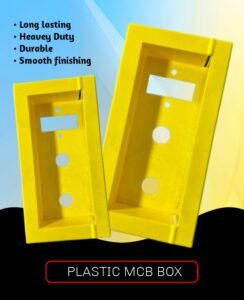

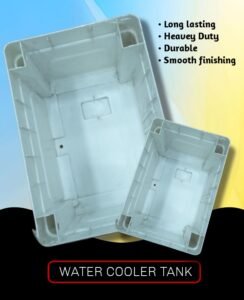

Household & Utility Plastic Parts – handles, knobs, containers, utility boxes, storage components, and co-parts.

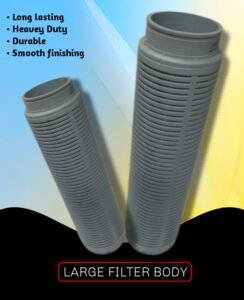

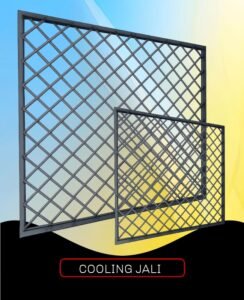

Industrial Plastic Components – gears, casings, machine covers, spacers, clamps, and engineering-grade heavy-duty moulded parts.

Metal Insert Moulded Parts – threaded inserts, bush fittings, and reinforced plastic-metal hybrid components for industrial use.

Packaging Plastic Components – caps, closures, containers, and customized injection moulded packaging solutions.

Agricultural Plastic Parts – irrigation components, sprayer nozzles, pipe fittings, and durable field-use accessories.

Electrical & Electronic Plastic Parts – switch housings, sockets, connectors, insulators, and covers.

Consumer & OEM Plastic Products – custom-designed plastic moulds for Original Equipment Manufacturers (OEMs).

Injection Moulding Machine Components – moulded machine parts and accessories for various industrial applications.

Precision Plastic Moulded Components – engineered small-size parts requiring high dimensional accuracy.

Bulk Plastic Component Manufacturing – high-volume production of standardized and custom parts.

Know More…